Standard Features:

- 4 / 8 / 12 filling stations.

- Servo driven on both volumetric pistons and nozzles.

- Various speed settings of liquid filling.

- Diving type and bottom up filing features less foaming during filling.

- Drip tray.

- Capability of recipe storage.

- Simple and quick tech mode setup.

- Track full / track empty sensors.

- Bottle mouth holder design for special applications (require to conduct our factory test).

- Bottle feed screw for handling irregular shaped containers (option).

- Motorized single lane sanitary conveyor. customized conveyor lengths are available upon request.

- Stainless steel construction.

- Capacity: up to 72 bottles per minute (BPM) on a water like liquid filling of 100 ml bottle for CVC 3036-12.12 headed filler.

- ISO 9001 : 2015 certified.

Product Specifications:

- Liquid Viscosity: up to 2000 cps

Container Specifications:

- Bottle Height: 2" to 8.66" (50 mm to 220 mm)

- Bottle Diameter / width: 1.18" to 3.94" (30 mm to 100 mm)

- Bottle Opening: ø10 mm ~ ø50 mm

Machine Specifications:

- Food grade liquid contact materials

- Piston Capacity: 50 ml / 100 ml / 250 ml / 500 ml / 750 ml

- Machine Weight:

CVC 3036-4: 1,367 lbs (620 kg)

CVC 3036-8: 2,083 lbs (945 kg)

CVC 3036-12: 2,226 lbs (1,010 kg)

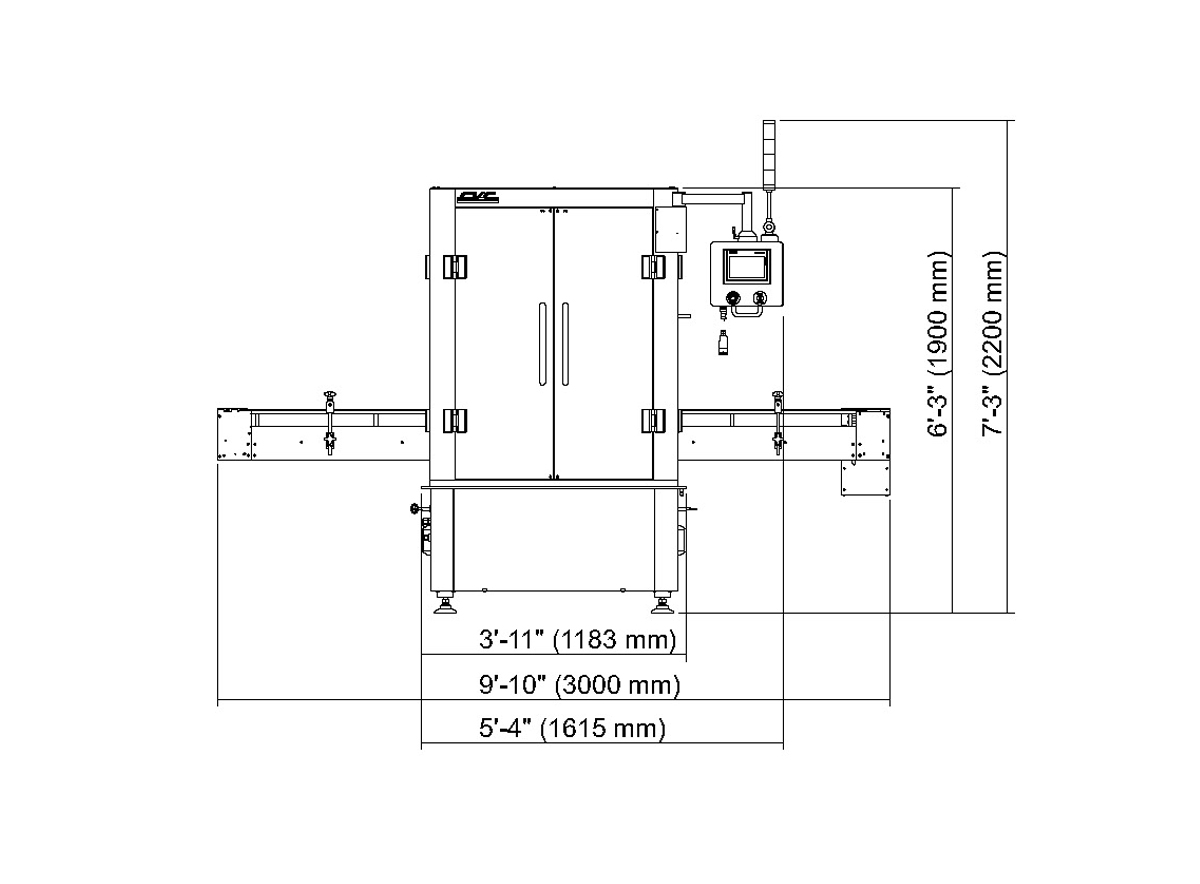

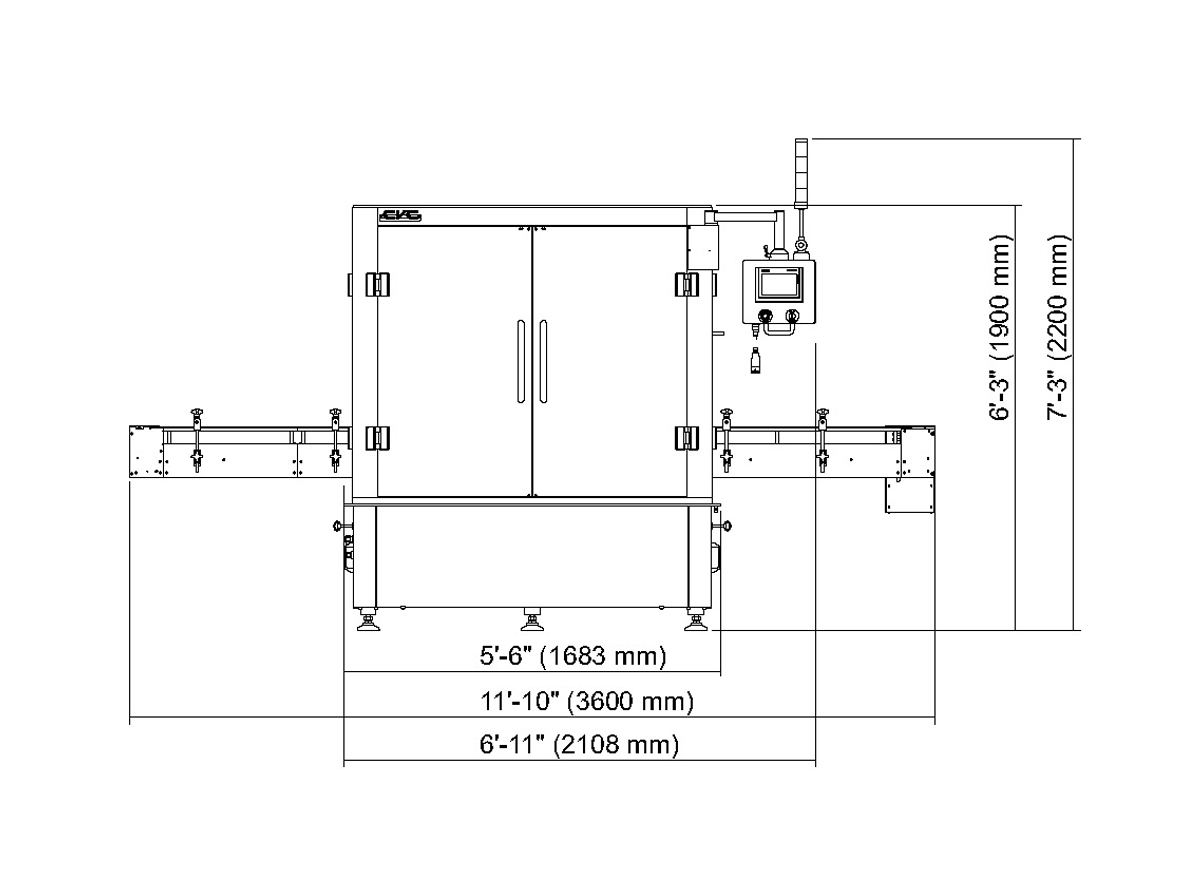

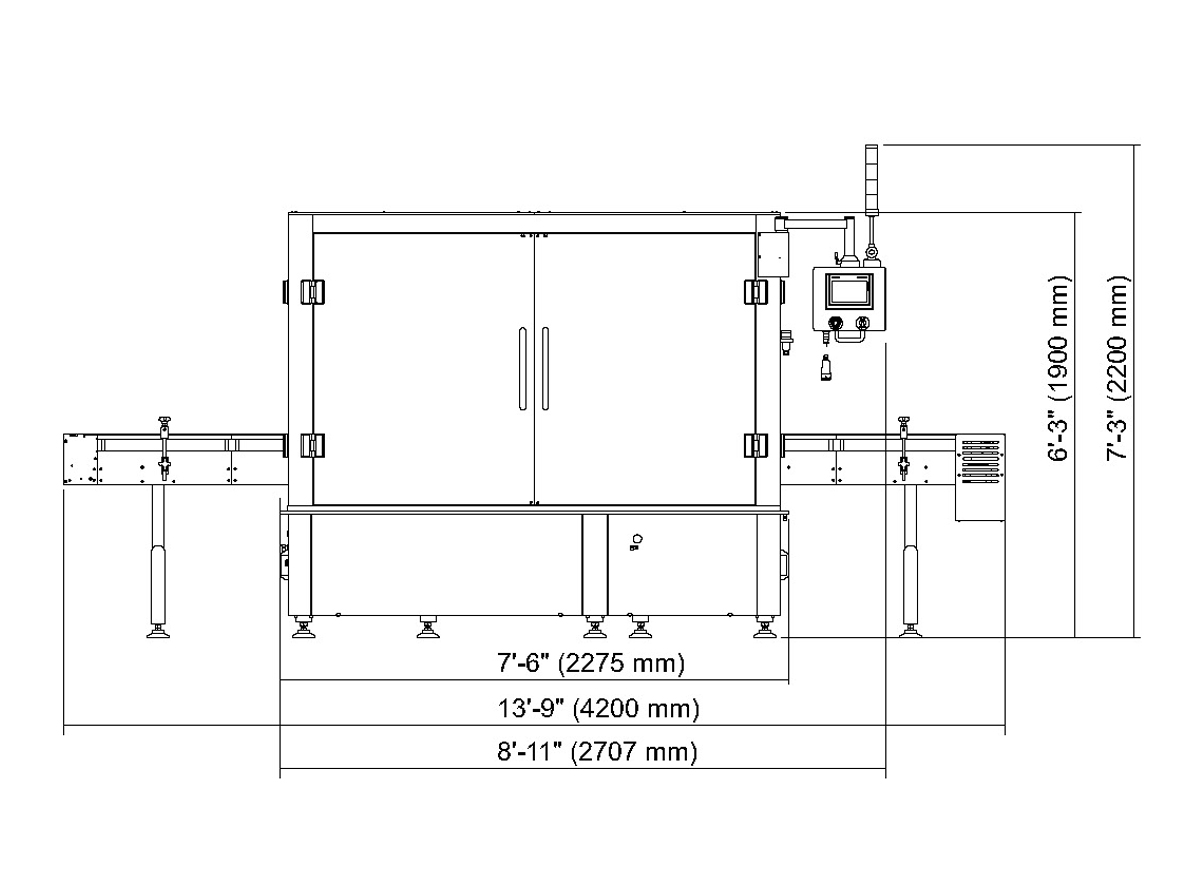

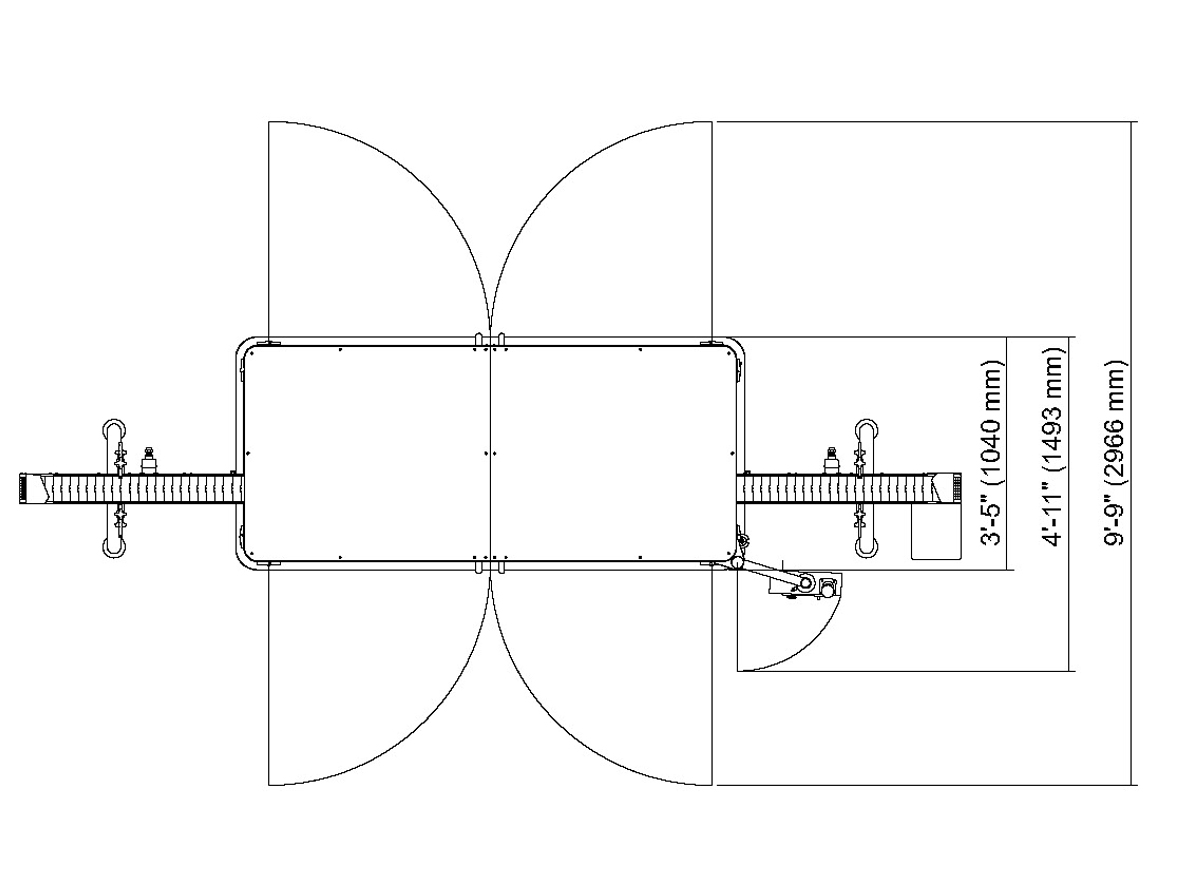

Machine Dimensions:

- CVC 3036-4: L. 118-1/8” x W. 41” x H. 86-5/8” (L. 3000 mm x W. 1040 mm x H. 2200 mm)

- CVC 3036-8: L. 141-3/4” x W. 41” x H. 86-5/8” (L. 3600 mm x W. 1040 mm x H. 2200 mm)

- CVC 3036-12: L. 165-3/8” x W. 41” x H. 86-5/8” (L. 4200 mm x W. 1040 mm x H. 2200 mm)

Air / Electrical Requirements:

- Power source:

380 V, 50/60 Hz, 3 phase

220 V, 50/60 Hz, single phase (USA) - Power consumption: 3100 VA - 6100 VA

- Air pressure: 87 psi (ISO 8573-1)

- Air consumption: 1.6 - 1.95 cfm

The dimensions shown are for standard machine. The conveyor can be extended: the length may vary based on selected options. This machine can run independently or be integrated into an automated packaging line. All CVC equipment is covered by a one-year parts warranty. Full Warranty details are included in our equipment proposals or can be found on our website.

Bottle Mouth Holders:

The dedicated bottle holders are required when bottle mouth opening is too small to be centered and aligned with fill nozzles.

Bottle Feed Screw:

The customized feed screw is driven by a servo motor. Operator can easily make quick changeover. It takes only few minutes for the mechanical changeover and its related setting from the touchscreen panel.

Shut-Off Nozzles and drip Tray:

Shut-off nozzles are strongly recommend for liquid with low viscosity.