TECHNICAL SPECIFICATIONS

AVAILABLE OPTIONS:

- Hot Stamp (Lot/Date Coding)

- Integrated Thermal Encoder (Lot/Date, Bar Code and Graphics)

- Adjustable Tilt for Tapered Bottles

- Bottle Rejection system ( air blow or cylinder)

- Clear Label Sensor

- Custom Wrap Belts and Feed Screw

- Infeed and Outfeed Conveyor Extensions

- Bar Code verification

- Low Label (Factory Installed Only)

- Missing Label Detection System (UV)

- Automatically generate the report on system

- Oufeed Turntable

- Missing Imprint Check system

- 21 CFR PART 11 compliance

- OPC UA for data collection

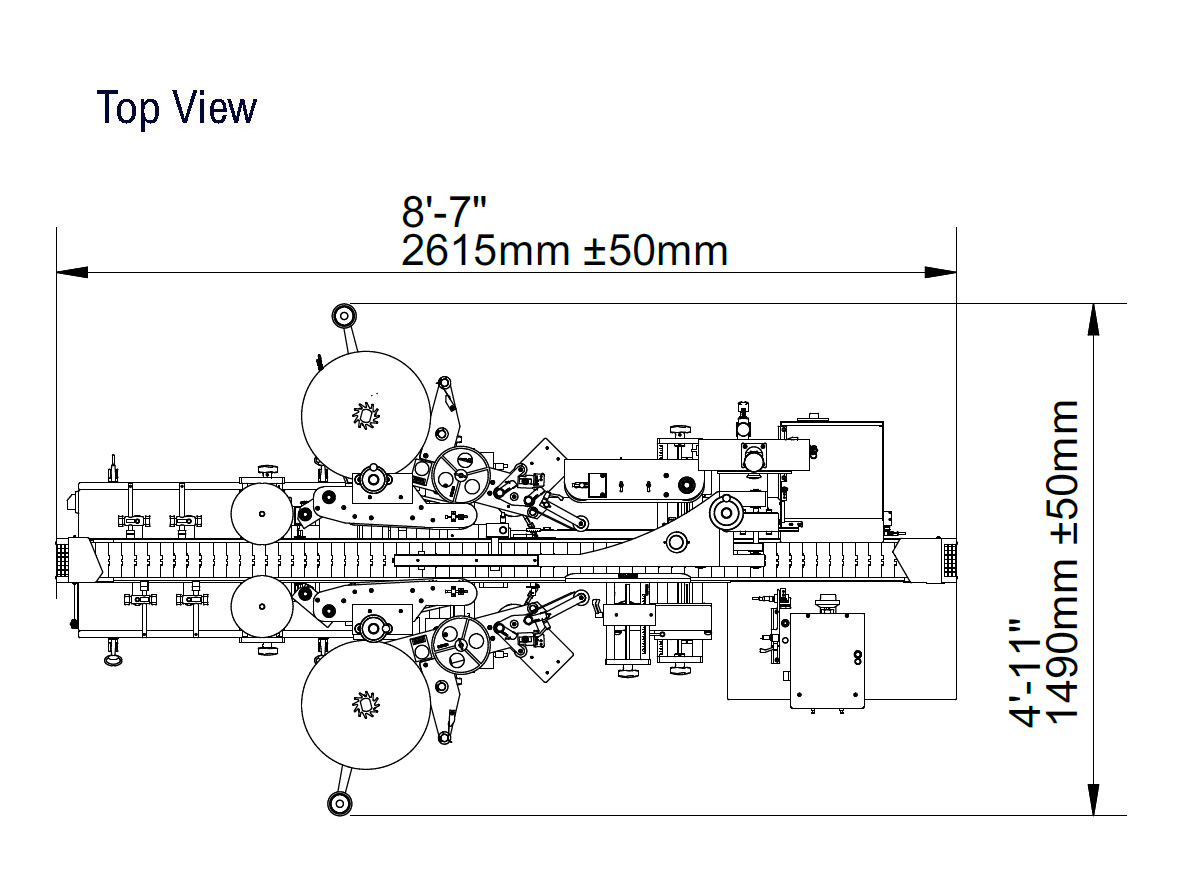

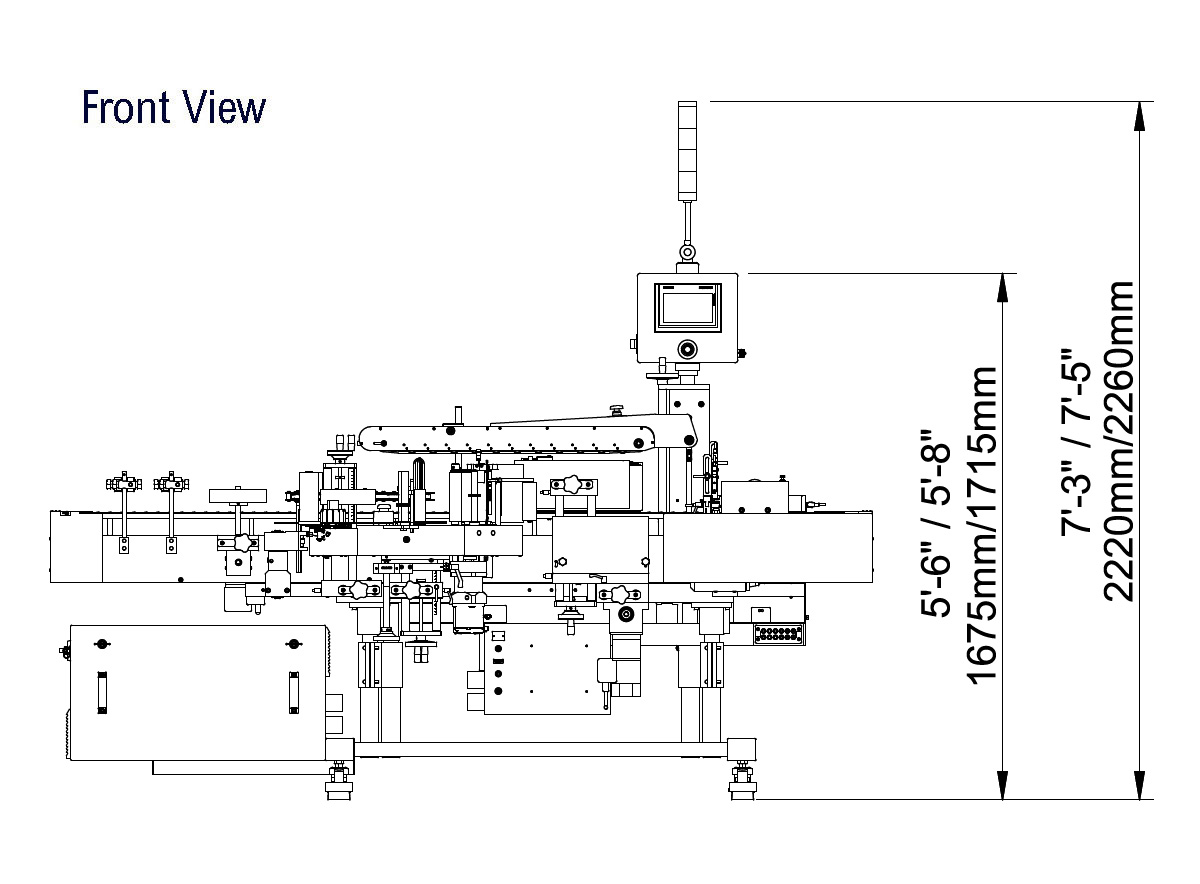

MACHINE LAYOUTS:

The dimensions shown are for standard machine. The conveyor can be extended: the length may var y based on selected options. This machine can run independently or be integrated into an automated packaging line. All CVC equipment is covered by a one-year parts warranty. Full Warranty details are included in our equipment proposals or can be found on our website.

All CVC labelers include our patented Self Set™ software which utilizes a high frequency encoder for extremely easy setup and wrinkle free labeling at the touch of a button.

Note: The actual rates may var y significantly depending on the following: products, product characteristics, required fill counts, quantity or volume, and bottle dimensions.