The CVC 6088-2R24 Automatic Rotary Powder Filling Machine is designed to fill powder products into containers provided to its infeed conveyor and transported through its rotary continuous motion mechanism. The Powder dosing uses servo motor driven auger dosing system for accuracy volume.

The overall machine construction takes most applicable regulatory considerations nto account: cGMP, FDA, and it meets the requirements of most integrated powder filling-packaging lines for pharmaceutical and nutraceutical industries.

STANDARD FEATURES

- Double head auger powder filling

- Siemens PLC control and Touch-Screen control panel provide easiness of adjustment and operation

- The Product dosing is done by a servo motor driven auger, dosing amount depends on the auger size (changeover part), and also depends on its rotation, which is settable from the HMI

- The Rotary funnels receive accurate amounts of powder dispensed by the auger; and while the funnels are rotating along with the filling starwheel, the powder will be filled into the bottles

- Enclosed design avoids product dust getting into mechanical/electrical system

- Changeover and disassembling of auger is simple and toolless

- Clean up is easy and quick

- No bottle no fill

- Machine stops when bottle stuck

- Machine stops when low air pressure

- All product contact parts are SUS 316 stainless steel and FDA approved or accepted materials

- The machine uses non-weld seamless one-piece SUS 316 auger, which ensures thorough washing, cross–contamination concerns are thus eliminated

TECHNICAL SPECIFICATIONS

AVAILABLE OPTIONS:

- Buffer hopper and vacuum generator system

- Nitrogen purging device

- Infeed/ outfeed starwheel assembly changeover

- Rotary filling station changeover

- Bottle holder block

- Filling nozzle

- Dosing auger

- Nitrogen purging connection

- Vacuum dust collector connection

- Vacuum powder feeding connection

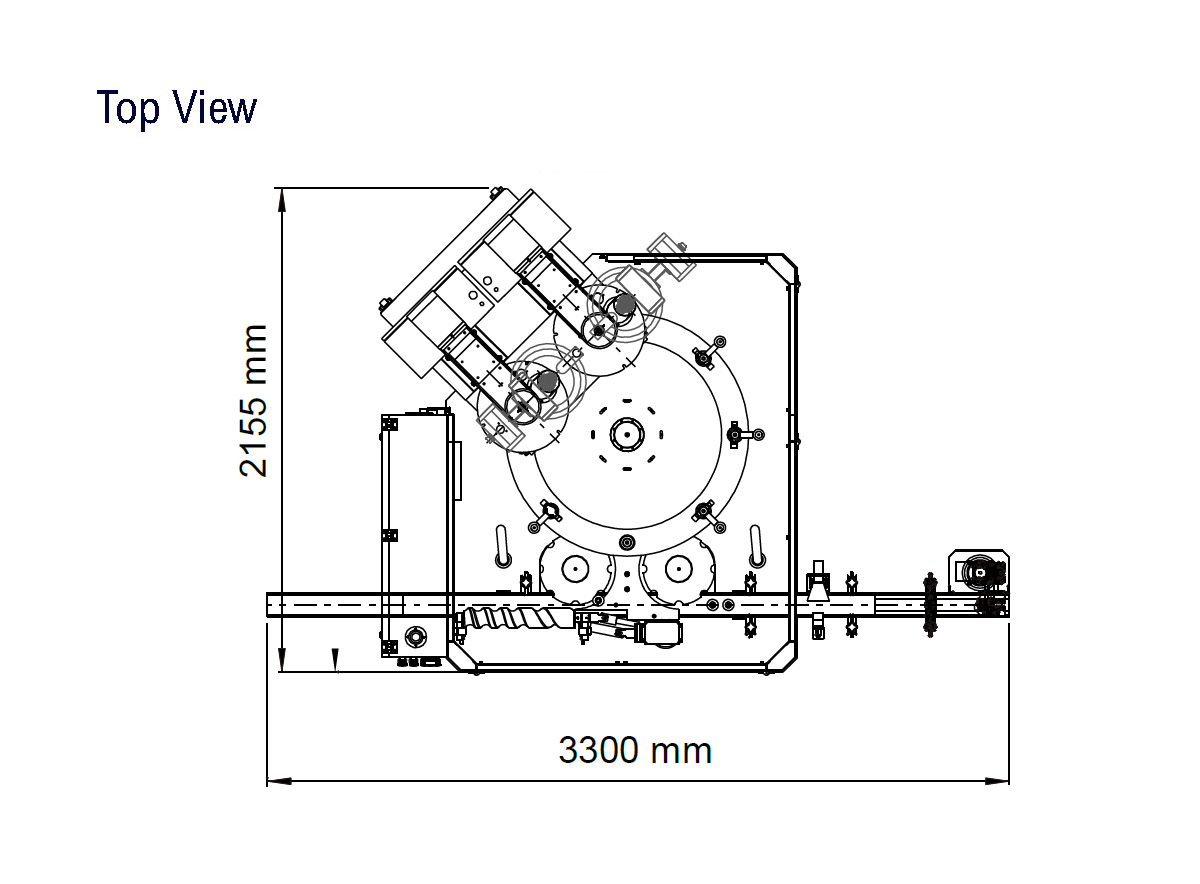

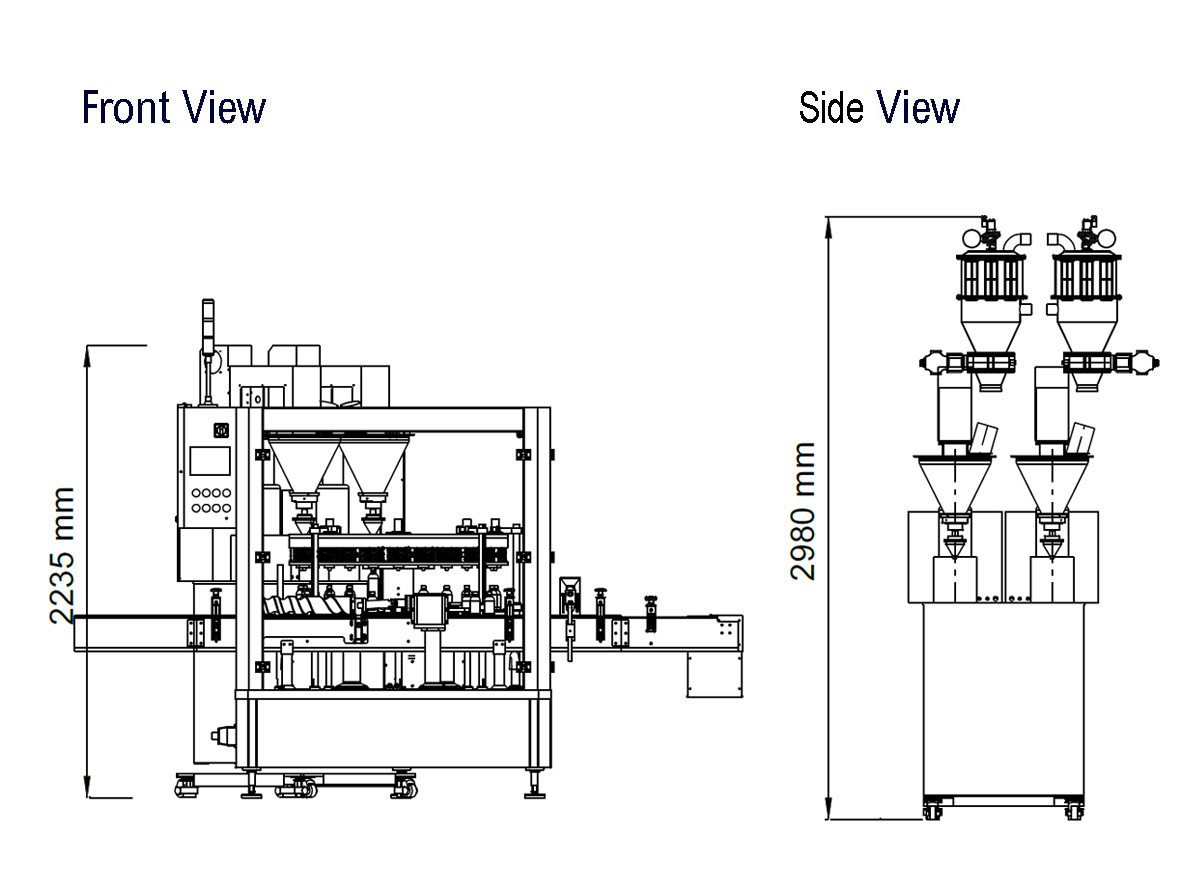

MACHINE LAYOUTS:

The dimensions shown are for standard machine with optional infeed and outfeed conveyor. Optional conveyor for bottle transporation is available upon request. This machine with an optional conveyor can run independently or be integrated into an automated packaging line. All CVC equipment is covered by a one-year parts warranty. Full Warranty details are included in our equipment proposals or can be found on our website.