TECHNICAL SPECIFICATIONS

AVAILABLE OPTIONS:

- Motorized sanitary conveyor (6" wide belt available)

- Tower lamp, torque metering (servo motor)

- Rejection system, reject confirmation

- 21 CFR Part 11 License

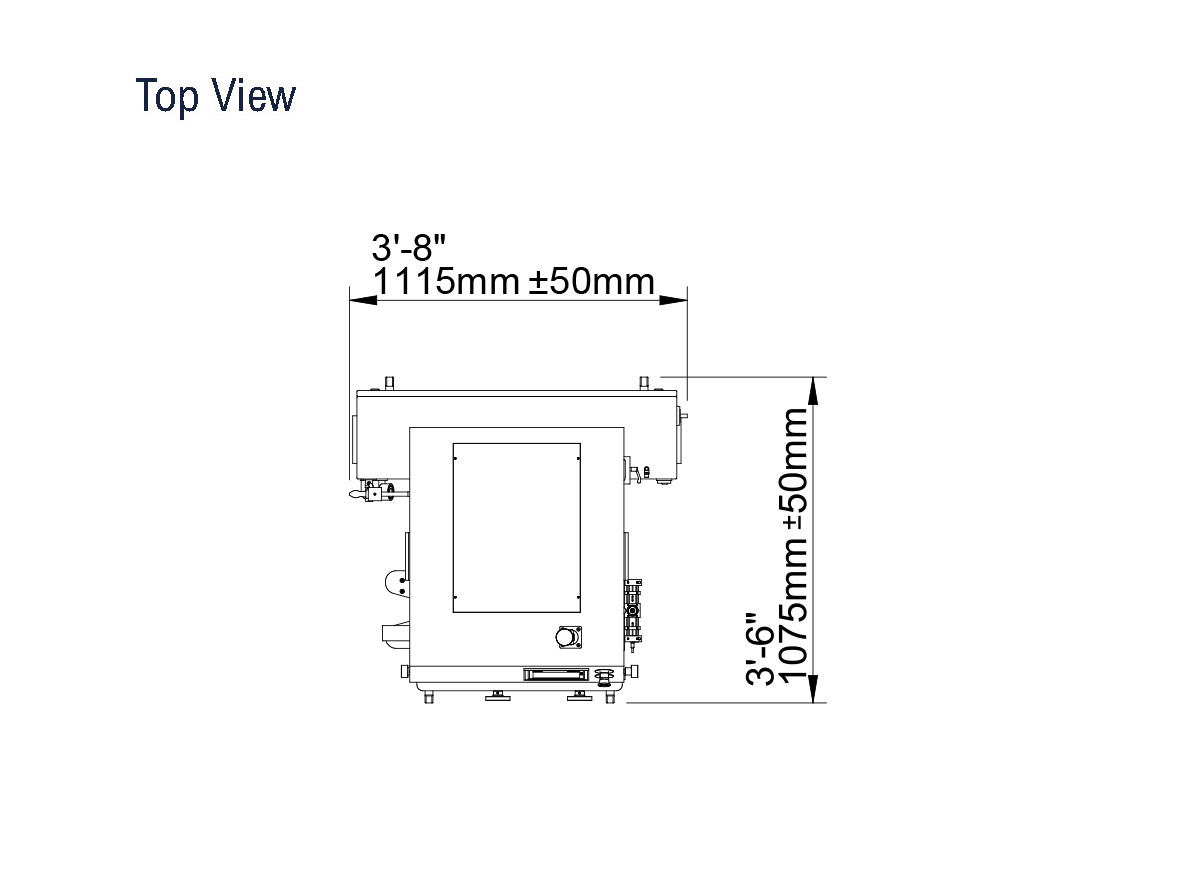

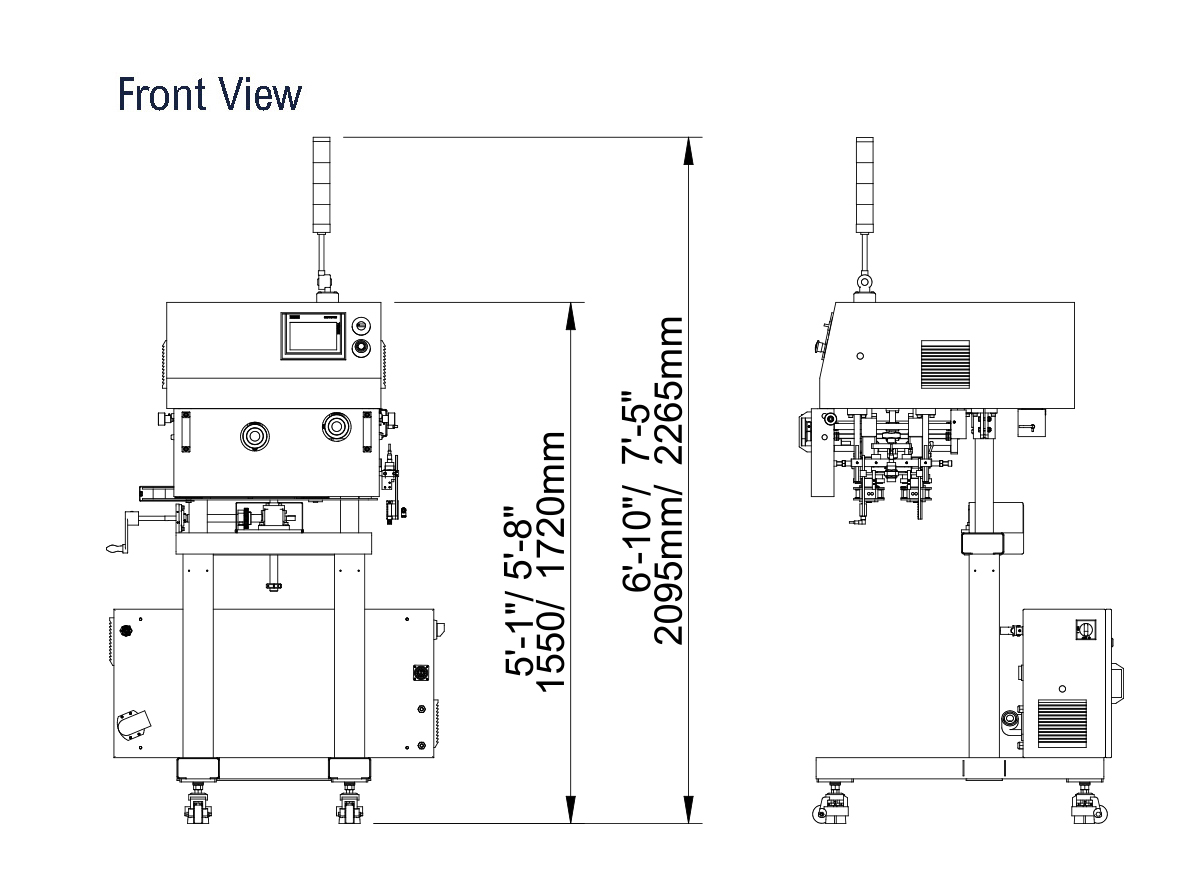

MACHINE LAYOUTS:

The dimensions shown are for standard machine. The conveyor can be extended: the length may var y based on selected options. This machine can run independently or be integrated into an automated packaging line. All CVC equipment is covered by a one-year par ts warranty. Full Warranty details are included in our equipment proposals or can be found on our website.