TECHNICAL SPECIFICATIONS

AVAILABLE OPTIONS:

- Infeed feed screw system for high speed applications

- Tower lamp

- 21 CFR Part 11 License

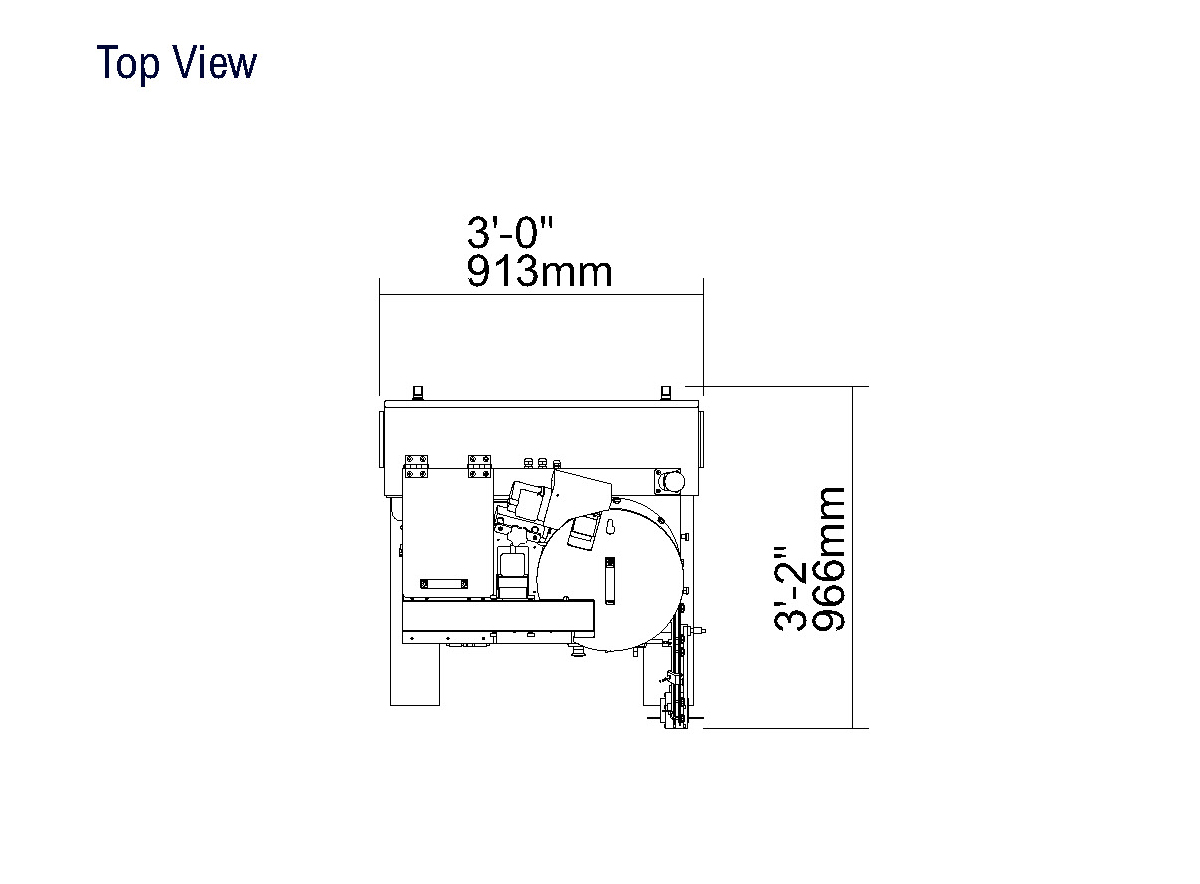

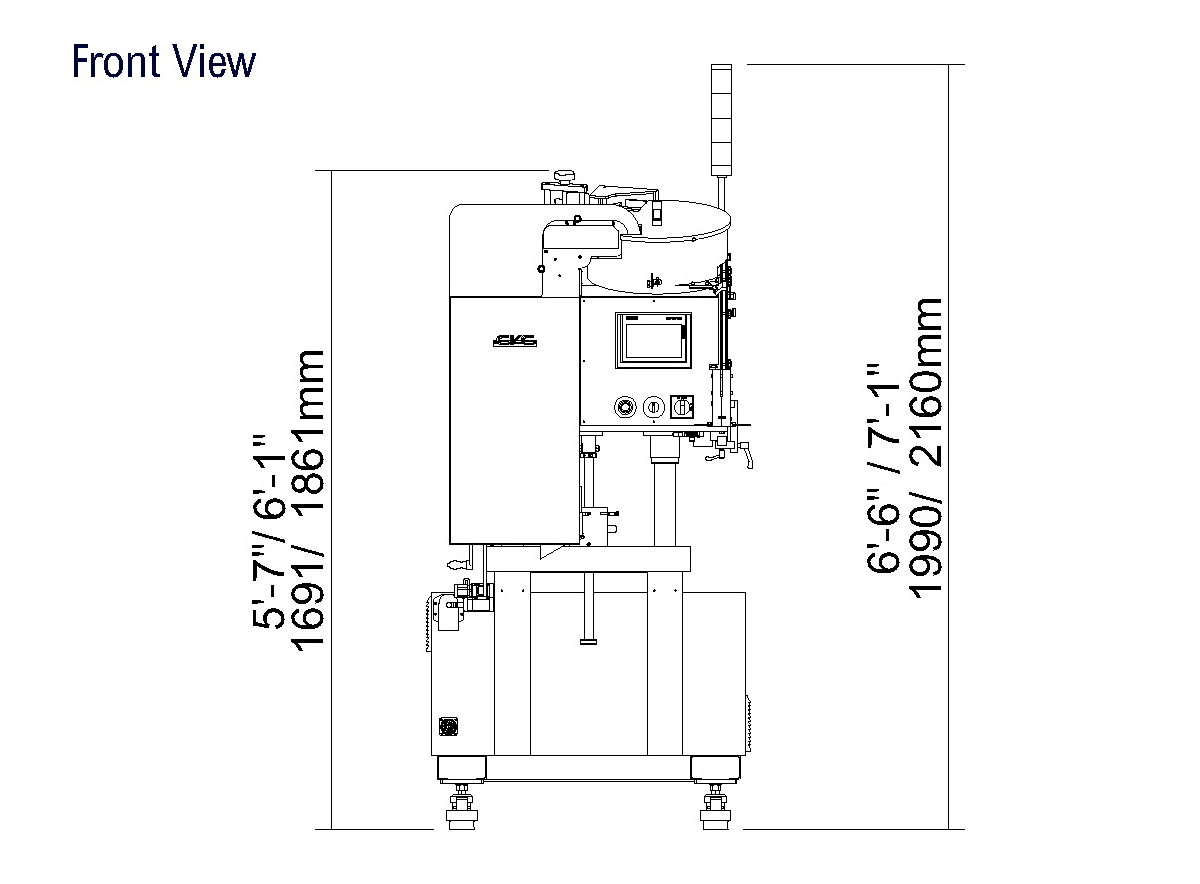

MACHINE LAYOUTS:

The dimensions shown are for standard machine. The conveyor can be extended: the length may var y based on selected options. This machine can run independently or be integrated into an automated packaging line. All CVC equipment is covered by a one-year parts warranty. Full Warranty details are included in our equipment proposals or can be found on our website.

1.25 : 1.00, Canister diameter cannot equal canister height.

Note: Rate is based on 1 gram canister with one insertion per bottle and canister size is 14mm Diam. X 18mm Ht.